Pre-engineered building is currently transform the construction or infrastructure industry in India. As PEB Manufacturers built the setup quickly, cost effective, have flexible design and can provide long lasting durability which makes it perfect for factories, warehouse, logistic center and showroom etc. But even the Top PEB Building Manufacturer Company in India can find the various issues at the time of installation, but a leading and Best PEB Plant in India like Ritu Tech N Build assures that every structure is designed & installed with care.

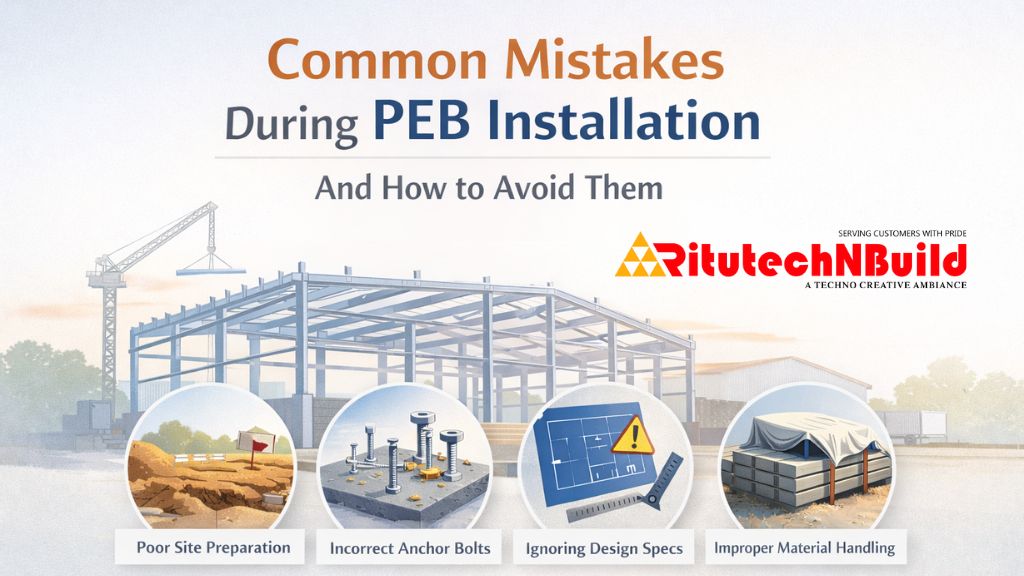

Here are the most common PEB installation mistakes and expert advice how to avoid them.

- Poor Site Preparation:

One of the major mistake while installing in Peb is not preparing the site properly. If the ground is uneven, not level correctly or lacks proper drainage – it can cause misalignment and long lasting structural problem.

How to Avoid This:

- Make sure certified engineer check the quality of steel and approves the quality of soil.

- Level and clear the ground properly before starting the installation.

- Setup sufficient drainage system to avoid water accumulation

The leading Pre Engineered Building Manufacturers in India like us always check the site before installation of the PEB structure.

- Incorrect Anchor Bolt Placement:

Anchor bolts are the backbone of any PEB structure just a minute misalignment can lead to delays, rework or uneven load distribution.

How to Avoid This:

- Use precise anchor bolt templates that is supplied by the manufacturer.

- Verify the alignment and depth before pouring concrete.

- Maintain the clear communication between the civil and steel teams.

That’s why collaborating with a leading PEB building manufacturer in India assures professional coordination and technical precision.

- Ignoring Design Specification:

A lot of contractors makes the mistake during installation, overlooking the design plans and engineering specifics. It can result in structural flaws and quality problems.

How to Avoid This:

- Follow the detailed erection drawings of the structure given by the PEB supplier.

- Do not use the substitute components without the engineers’ approval.

- Make sure that only experienced and relevant workers take care of crucial tasks.

Trustworthy Pre Engineered Building Manufacturers in India always provide accurate design documents which make sure to use them as your ultimate reference during installation.

- Poor Handling & Storage Of Materials:

PEB components like panels, purlins and main frames can be harmed – if they’re not handled carefully or if they’re left in open space in bad weather.

How to Avoid This:

- Make sure to store materials on flat ground with a reliable and precise amount of support.

- Make sure to keep the steel coated and covered until you’re ready to install it.

- Utilize cranes and other equipments that are appropriate for handling steel.

Good material management is crucial to uphold the quality that pre-engineered building manufacturers can ensure.

Conclusion:

Avoiding these type of errors can really boost the strength, longevity and efficiency of your PEB structure. Teaming up with a reputable company like Ritu Tech N Builds is recognized as one of the Best PEB Plants in India and a Top PEB Building Manufacturer Company in India which assures the flexible design, production and installation of the PEB Structure. If you’re looking for the leading PEB building manufacturer in India or trustworthy PEB Suppliers in India, our skilled engineer team provides quality-focused steel material, budget-friendly construction and prompt solutions for every project.