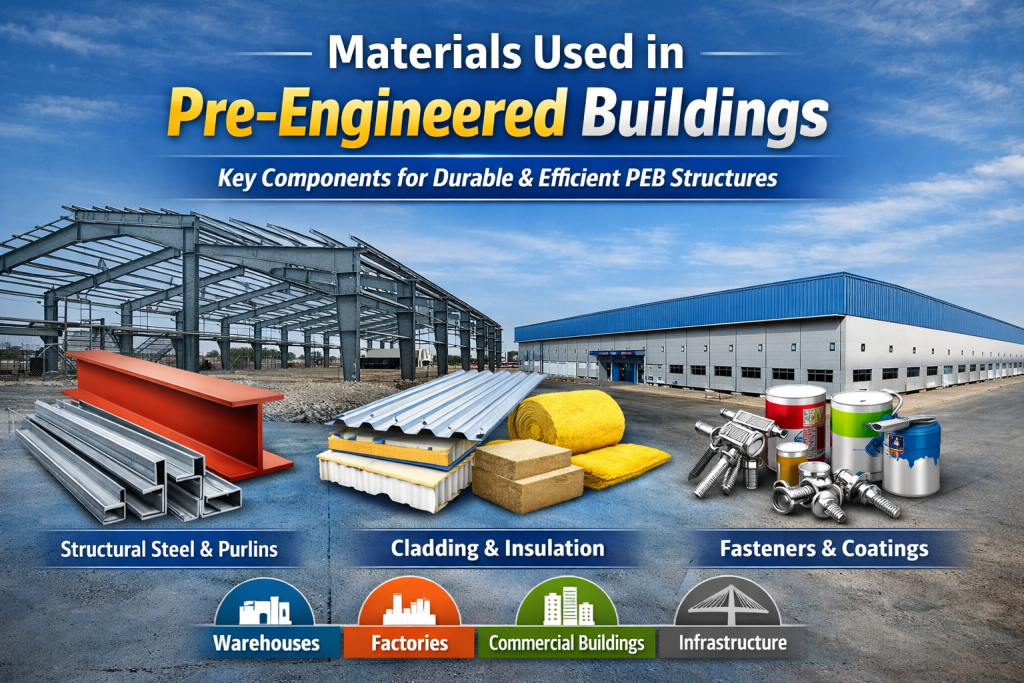

Pre-engineered buildings have revolutionized the construction sector in India by offering quicker execution, cost effectiveness, and enhanced structural performance. With ever-increasing demand for Industrial Shed, Warehouses, Factories, Commercial Building, and Infrastructure projects, choosing the right material for Pre-Engineered Buildings is very vital for durability and safety. As a leading pre-engineered building manufacturers in India, Ritu Tech N Build prioritize the use of high quality material that meets the both national and international standards which is suitable for Indian weather conditions. This guide outlines all the key materials used in PEB construction and explains the significance.

What are Pre Engineered Building?

Pre-engineered building are steel structures that are designed and built in a factory then it is shipped to the site for assembly with bolted connections. Unlike traditional construction method, PEB Manufacturers uses advanced design software to optimize steel usage, speed up completion times and less material waste. Nowadays, pre-engineered building manufacturers favors this approach for industrial, commercial and large span structure because of its flexibility and performance benefits.

Key Components Used in Pre Engineered Building:

-

Purlins & Grit:

Purlins & Grits are secondary structural elements crafted from cold formed steel typically shaped like Z or C.

Function:

- Support roof & wall sheeting

- Transfer loads to main frame

- Enhances overall structural stability

Why they are preferred:

These components are lightweight, resistant to corrosion and budget friendly which makes them a popular choice among PEB manufacturers to minimize dead load while maintain the strength.

-

Roof Wall & Cladding:

Roof wall & cladding shield building the element while also boosting the visual appeal.

Functions:

- Color coated galvanized steel sheet

- Aluminum Sheets

- Sandwich panels

Why they are preferred:

Cladding materials offers several advantages like being weather resistant provide a great thermal performance and an attractive finish. In India, manufacturers choose these materials depending on local climate and how these buildings is going to be used.

-

Paints & Coating:

A protective coating plays a super important role for increasing the lifespan of steel structures.

Function:

- Red oxide primer

- Epoxy coating

- Polyurethane paint

- Hot dip galvanization

Why they are preferred:

They help in stop corrosion, chemical damage and rust which makes them vital for industrial setting and coastal areas.

-

Structural Steel:

It serves as the foundation for pre-engineered building.

Function:

- Built up section

- Hot rolled section

- Primary Frames

Why they are preferred:

The high quality steel is crucial for ensuring safety and longevity in pre-engineered structure with its impressive strength to weight ratio, accurate engineering and extended lifespan.

-

Insulation Material:

Insulation improves thermal comfort and boosts energy efficiency.

Function:

- Glass wool

- Rock Wool

- PUF panels

Why they are preferred:

Controlling temperature has its perk, like reducing the noise and saving on energy bills which makes its perfect for warehouse, factories and cold storage facilities all over India.

-

Fasteners and Bolts:

Fasteners plays a crucial role in maintaining structural integrity and simplifying assembly.

Function:

- High tensile bolt

- Self-drilling screw

- Anchor bolts

Why they are preferred:

We at Ritu Tech N Build enables quicker installation, straightforward dismantling and a strong load bearing capacity which is a major benefit of PEB system.

Why These Components Are Preferred?

The components used by PEB Building Structure Manufacturer in India because they provide a great balance between strength, durability and efficiency. The high quality structural steel offers fantastic load bearing capabilities while keeping the overall weight of the building down. Galvanized purlins, grits and high quality fasteners provides long lasting corrosion resistance and structural integrity. Good cladding and insulation material enhances the thermal performance, energy efficiency and comfort indoors.

The protective paint and coats helps in protecting against the harsh weather conditions. When all these components works together sit allows in fast construction, reduced maintenance cost, design flexibility and consistent quality which makes, pre-engineered building a reliable and budget friendly construction option.

Advantages of Pre Engineered Building:

- Faster construction compared to traditional structures

- Budget friendly and resource efficient

- Flexible design option and simple to expand

- Minimum maintenance need

- Eco friendly and sustainable

- Highly durable with good earthquake resistance

Common Mistakes to Avoid While Building the Structure:

- Using the low steel quality

- Overlooking the insulation need

- Insufficient corrosion protection

- Lack of proper design and load assessment

- Going with inexperienced PEB manufacturers

Why to Choose Ritu Tech N Build?

Ritu Tech N Build is one of the best PEB plants in India, offering total solutions-from design to execution. Backed by our state-of-the-art manufacturing plant, superior work force of engineers, and stringent quality control, we manufacture tailor-made pre-engineered buildings according to our client’s needs while adhering to industry standards.

Final Thoughts:

Selecting the materials involved in pre-engineered buildings is key to making smart construction choices. Partnering up with reliable pre-engineered building manufacturers in India, such as Ritu Tech N Builds, assures premium quality, durability and cost-effectiveness for your project. PEB structures aren’t merely a building option—they’re a wise investment for the future.

Frequently Asked Question:

- Why is structural strength preferred in PEB building?

Structural steel offers high strength, durability, design flexibility and resistance to seismic and wind loads.

- What type of insulation is used in pre-engineered building?

Glass wool, rock wool and PUF panels are widely used for thermal and sound insulations.

- Are PEB buildings suitable in India for all industries?

Yes, Peb buildings are perfect for warehouse, factories, commercial spaces, logistics hub and industrial units.

- How long does a pre-engineered building last?

With proper material and coatings, PEB structure can last for 30 – 50 years with minimum maintenance.